UK Workplace Exposure Limits Explained

A workplace exposure limit (or WEL) is the legal maximum concentration of a hazardous substance in the air that an employee can be exposed to over a set time. It acts as a critical safety ceiling for invisible dangers like gases, dusts and vapours. In the UK, these limits are set by the Health and Safety Executive (HSE) to shield workers from the harmful health effects of chemical exposure.

Put simply, a WEL is a legal limit on the amount of a hazardous substance in the air, averaged over a specific period. These limits are a vital part of UK law, specifically the Control of Substances Hazardous to Health (COSHH) Regulations, designed to protect the long-term health of your team.

Understanding the Purpose of Workplace Exposure Limits

Think of a workplace exposure limit as a speed limit for the air your team breathes. Just as driving too fast raises the risk of an accident, breathing in too much of a hazardous substance increases the risk of illness. WELs give you a clear, legally enforceable boundary to manage these occupational health risks properly.

These limits are not just numbers picked at random; they are based on solid scientific evidence about the concentration at which substances start to cause harm. Getting to grips with these invisible threats is a fundamental part of running a safe and productive workplace, especially in industrial settings where airborne contaminants are a daily reality.

The Legal Framework in the UK

In the United Kingdom, WELs are a cornerstone of the Control of Substances Hazardous to Health (COSHH) Regulations. Under COSHH, employers have a legal duty to prevent—or at least adequately control—their employees’ exposure to hazardous substances. Sticking to the established workplace exposure limit is a non-negotiable part of proving you have things under control.

But compliance is much more than just knowing the numbers. It demands a systematic approach that includes:

- Risk Assessment: Pinpointing the hazardous substances on-site and working out how, when and where workers might be exposed.

- Control Measures: Putting practical strategies in place to reduce exposure, like better ventilation systems or changing your processes.

- Monitoring: Regularly measuring the concentration of airborne substances to make sure your controls are working and WELs are not being breached.

- Record Keeping: Maintaining detailed records of your assessments, monitoring results and the control measures you have implemented.

A workplace exposure limit (WEL) represents a point on a scale of exposure. Below this point, according to current scientific knowledge, no harm to the health of workers is expected to occur as a result of exposure by inhalation day after day.

Before we dive deeper, let’s break down these core ideas into a simple table.

Key Workplace Exposure Limit Concepts at a Glance

This table summarises the key terms you’ll encounter when dealing with WELs and COSHH regulations in the UK.

| Concept | Brief Description | Primary Goal |

|---|---|---|

| WEL (Workplace Exposure Limit) | The maximum legal concentration of an airborne hazardous substance over a specified time. | Prevent occupational illness from chemical exposure. |

| COSHH Regulations | The UK law requiring employers to control substances that are hazardous to health. | Provide a legal framework for protecting worker health. |

| Risk Assessment | The process of identifying hazards and evaluating the risk of exposure. | Proactively identify and plan to mitigate potential harm. |

| Control Measures | Actions taken to reduce or prevent exposure (e.g., ventilation, PPE). | Minimise worker contact with hazardous substances. |

| Air Monitoring | The practice of sampling and analysing air to measure substance concentration. | Verify that control measures are effective and WELs are not exceeded. |

Understanding these concepts is the first step towards building a robust and compliant safety programme that genuinely protects your team.

Why WELs Are Critical for Worker Health

The whole point of a workplace exposure limit is to prevent both immediate (acute) and long-term (chronic) health problems. Different substances affect the body in different ways and over different timescales, which is why WELs are defined for distinct periods.

Some chemicals can cause immediate issues like irritation, dizziness or even poisoning after just a brief, high-level exposure. Others are more insidious, leading to serious conditions like cancer or respiratory diseases after years of lower-level exposure. By setting limits for both short and long-term periods, the HSE provides a framework to protect workers from the full spectrum of potential harm, making every workplace safer.

The Evolution of UK Worker Safety Standards

Today’s robust framework for workplace exposure limits did not just appear out of nowhere. It was forged over decades of industrial experience, scientific breakthroughs and, sadly, hard-won lessons from workplace tragedies. Understanding this history is key to grasping just how vital these regulations are for protecting today’s workforce.

If you look back just a few decades, you’ll see a starkly different—and far more dangerous—landscape for UK workers. Before the stringent safety standards we have now, millions were routinely exposed to hazardous substances with few, if any, effective controls. The risks were often invisible and misunderstood, leading to widespread occupational illnesses that could take years, or even decades, to show themselves.

This context proves that today’s regulations are not arbitrary red tape. They are the direct result of methodical research and a deep societal commitment to preventing the devastating health consequences that previous generations had to endure.

A Look Back at Past Exposures

The sheer scale of historical workplace exposure is sobering. In Great Britain, data from the 1990s showed that nearly seven million workers were exposed to at least one of 64 known carcinogenic agents on the job.

According to the CAREX database, which was part of the Europe Against Cancer programme, the top 30 carcinogens accounted for 99.5% of this exposed population. Substances like radon, industrial chemicals and even sunlight posed huge, unmanaged risks in major sectors like manufacturing and construction.

This widespread exposure created a legacy of occupational diseases, especially lung conditions caused by inhaling dust and fibres. The gradual implementation and tightening of exposure limits have directly led to a dramatic reduction in these illnesses, giving us tangible proof of their life-saving impact.

The journey towards safer workplaces has been a progressive one, built on scientific evidence. Each new workplace exposure limit represents a crucial step forward, closing a door on a risk that was once accepted as a part of the job. This evolution reflects a fundamental shift in how we value worker health and safety.

From Reactive Measures to Proactive Protection

Early industrial safety efforts were often reactive, responding to accidents and disasters only after they had already happened. The modern approach, underpinned by regulations like COSHH, is fundamentally proactive. It demands that employers anticipate risks, assess them thoroughly and implement controls before anyone can be harmed.

This shift is central to the very concept of the workplace exposure limit. It moves safety from being a matter of chance to a matter of scientific certainty, creating environments where health is actively protected rather than just hoped for. The focus now is all on prevention through diligent monitoring and management.

For anyone looking to strengthen their safety protocols, our articles on workplace safety in the UK offer some valuable insights.

Understanding these standards is one thing, but embedding them in your company culture often requires developing effective educational programmes. For example, a well-structured training initiative can ensure every team member understands the risks and the control measures in place. You can learn how to create a high-impact health and safety course to better implement these principles. This kind of continuous education is essential for maintaining a culture of safety that adapts to new challenges and technologies, ensuring the hard-learned lessons of the past continue to protect workers today and tomorrow.

Decoding the Different Types of Exposure Limits

Not all workplace exposure risks are created equal. Some hazardous substances cause damage slowly over many years, while others can have an immediate, dangerous impact. To offer real protection, a single exposure limit just will not cut it. Instead, regulators define different types to cover all the bases.

Getting to grips with these different metrics is fundamental for accurate risk assessment and effective control. The three main types you’ll come across are the Time-Weighted Average (TWA), the Short-Term Exposure Limit (STEL) and the Ceiling Limit. Each one serves a very distinct purpose in keeping workers safe from both chronic and acute health problems.

Time-Weighted Average (TWA): The Marathon Limit

The most common type of workplace exposure limit is the Time-Weighted Average (TWA). Think of it as a worker’s ‘average daily dose’ of a substance, calculated over a standard eight-hour workday and a 40-hour work week. It’s designed to manage the risk of long-term, chronic health issues that creep up from repeated exposure over months or years.

This limit allows for the natural ebb and flow of concentration levels during a shift. For instance, a worker might have a brief period of higher exposure while doing a specific task, followed by a long stretch of very low exposure. As long as the average across the entire eight hours stays below the TWA, the exposure is considered under control.

The TWA’s main job is to prevent occupational diseases like lung conditions or cancer, which often result from the cumulative effects of a substance. It’s the marathon of exposure management, focused on sustainable safety over a lifetime of work.

Short-Term Exposure Limit (STEL): The Sprint Limit

While the TWA protects against long-term harm, some substances can be dangerous even in very small doses over short periods. This is where the Short-Term Exposure Limit (STEL) comes into play. You can think of the STEL as a ‘sprint limit’—a higher concentration that workers can be exposed to for a brief time without suffering immediate effects.

Typically, a STEL is measured over a 15-minute period and must never be exceeded at any point during the workday. It’s specifically designed to protect against acute health problems such as:

- Eye or skin irritation

- Dizziness or headaches

- Coughing or respiratory distress

Even if the eight-hour TWA is well within its limit, a sudden spike in concentration could still be harmful. The STEL provides that extra layer of protection against these dangerous peaks, ensuring short but intense exposures are also managed safely.

A simple way to view it: the TWA protects against the slow, creeping damage of chronic exposure, whereas the STEL guards against the immediate, sharp shock of an acute exposure. Both are vital for a complete safety strategy.

Ceiling Limit: The Absolute Maximum

Finally, we have the Ceiling Limit. As the name suggests, this is the ‘absolute maximum’ concentration of a hazardous substance that should never, ever be exceeded—not even for a split second. This limit is reserved for highly toxic or fast-acting substances that can cause serious injury or death from even instantaneous exposure.

Unlike the TWA or STEL, there is no time component to average out a ceiling limit. Any measurement above this value represents a dangerous and unacceptable breach of safety protocols.

To help clarify how these limits differ, here’s a quick comparison:

Comparing TWA, STEL, and Ceiling Exposure Limits

| Limit Type | Measurement Period | Purpose | Example Scenario |

|---|---|---|---|

| TWA | 8 hours | Prevents chronic, long-term health effects from cumulative exposure. | A factory worker exposed to solvent fumes throughout their shift. |

| STEL | 15 minutes | Prevents acute, short-term effects like irritation or dizziness from exposure spikes. | A lab technician handling a volatile chemical for a brief task. |

| Ceiling | Instantaneous | Prevents immediate, severe health risks from highly toxic substances. | Emergency responders entering an area with a known toxic gas leak. |

These three limits—TWA, STEL, and Ceiling—work together to create a robust framework for managing airborne hazards. By understanding the distinct role of each, you can implement more effective control measures and ensure your team is protected from every angle. This multi-faceted approach is central to maintaining a safe and legally compliant workplace.

How to Measure and Monitor Workplace Air Quality

Knowing the different types of workplace exposure limits is one thing; putting that knowledge into practice is another. Proper measurement and monitoring of your workplace air quality is not just a box-ticking exercise for regulators. It’s the only way to prove your control measures are actually working and your team is genuinely protected.

This process is more than just buying a piece of equipment. It demands a smart approach to sampling, the right choice of instruments and meticulous record-keeping. By moving from theory to practical action, you can turn invisible chemical threats into tangible, manageable data, keeping your workplace safe and compliant.

Developing a Robust Sampling Strategy

You cannot manage what you do not measure. That’s why a well-thought-out sampling strategy is the bedrock of any successful air quality monitoring programme. The aim is simple: collect samples that accurately represent what your employees are really breathing day in, day out.

There are three main ways to go about this, each giving you a different piece of the puzzle.

- Personal Sampling: This is the gold standard for understanding individual exposure. A small, lightweight monitor is worn by an employee right in their breathing zone—near their nose and mouth—for their entire shift. It delivers the most accurate data for checking an individual’s exposure against their workplace exposure limit.

- Area Sampling (or Static Sampling): This involves fixing a monitor in one spot to measure the general concentration of a substance in that area. It’s perfect for pinpointing high-risk zones, checking if your ventilation is up to scratch or keeping an eye on a potential leak source.

- Grab Sampling: Think of this as a quick snapshot. Using a portable device, you take an instantaneous reading to check for immediate dangers, like before someone enters a confined space or after a suspected chemical leak.

Most of the time, the best strategies cleverly combine these methods to build a complete, 360-degree view of the workplace environment.

Choosing the Right Instrumentation

Once your strategy is set, picking the right tools is absolutely crucial. The quality and type of your equipment will make or break the reliability of your data. For countless industries, precision gas analysers are the essential tool for getting the accurate readings needed to prove you’re meeting every workplace exposure limit.

The specific analyser you choose will depend entirely on the job at hand. For instance, a lightweight, portable gas analyser is ideal for grab sampling or for a safety officer who needs to move between different sites. It gives you the power to do quick spot checks and get immediate answers wherever you are.

On the other hand, a fixed monitoring system is designed for continuous, 24/7 analysis in a high-risk area, like around a heat treatment furnace or a chemical storage facility. These systems can be set up to sound an alarm if concentrations creep towards a danger point, giving you an immediate warning before it becomes a real problem.

The right instrument does more than just collect data; it provides confidence. Knowing your measurements are precise and reliable is fundamental to making informed decisions about worker safety and COSHH compliance.

Getting to grips with what different instruments can do is key. To get a better feel for the technology, it’s worth exploring how a modern indoor air quality monitor works, as it can offer valuable insight when picking the right fit for your facility.

Essential Best Practices for Monitoring

A great air monitoring programme is built on consistency and meticulous best practices. Following a clear, repeatable workflow ensures your data is not only accurate but will also stand up to scrutiny during an HSE inspection.

1. Regular Instrument Calibration

Calibration is completely non-negotiable. It’s the process of checking your instrument against a known standard concentration to make sure its readings are spot-on. Without it, instrument ‘drift’ can cause false readings, potentially hiding a dangerous over-exposure or causing unnecessary panic.

2. Meticulous Data Logging

Your monitoring devices need to log data consistently. This builds up a detailed history of exposure levels over time, which is invaluable for spotting trends, judging the long-term success of your controls and investigating any incidents that occur.

3. Comprehensive Record-Keeping

Under COSHH, you are legally required to keep records of your risk assessments and any exposure monitoring you carry out. These records must be detailed, well-organised and kept for the required period—which can be up to 40 years for certain substances. This paperwork is your proof of compliance.

By weaving together a smart sampling strategy, using high-quality instruments and sticking to these best practices, you can build a monitoring programme that actively protects your people and ticks every legal box.

Achieving and Maintaining COSHH Compliance

Knowing the theory behind a workplace exposure limit is one thing, but putting that knowledge into practice to achieve and maintain compliance is where it really counts. Under the UK’s Control of Substances Hazardous to Health (COSHH) regulations, this is not just about ticking boxes to avoid fines. It’s about creating a robust, systematic process to actively protect your workforce from harm, day in and day out.

True compliance demands a clear workflow, starting from identifying the risks and ending with solid, long-term controls. The Health and Safety Executive (HSE) expects employers to follow this structured path, proving that safety is woven into the fabric of their operations, not just an afterthought.

The Core COSHH Workflow

The journey to full COSHH compliance always kicks off with a detailed risk assessment. You need to pinpoint every hazardous substance in your workplace and figure out exactly how your employees might be exposed to it. For a wider perspective on hazard identification, it helps to understand broader classifications like the nine classes of dangerous goods, which provide a solid framework for recognising common dangerous properties.

Once you’ve got a handle on the risks, the next step is to put control measures in place. This is where the ‘hierarchy of controls’ comes in—a tried-and-tested framework that prioritises the most effective solutions first.

The hierarchy of controls is a cornerstone of modern workplace safety. Its core principle is simple but powerful: always try to eliminate the hazard at its source, rather than just relying on Personal Protective Equipment (PPE) as a default fix.

This practical mindset ensures you’re making real, meaningful changes to the working environment itself. After all, engineering out a hazard is always going to be more effective than just asking someone to wear a mask.

Implementing the Hierarchy of Controls

This framework gives you a clear pecking order for managing risks, starting with the most effective and working your way down.

- Elimination: Can you get rid of the hazardous substance entirely? A classic example is switching to a completely different, safer material for a process.

- Substitution: If you cannot eliminate it, can you swap it for a less dangerous alternative? This is often the next best thing.

- Engineering Controls: This is about physically separating people from the hazard. Think installing local exhaust ventilation systems to suck fumes away at the source or enclosing a noisy or dusty process.

- Administrative Controls: Here, you change the way people work. This could mean limiting the time workers spend in a high-risk area, improving training or updating safety procedures.

- Personal Protective Equipment (PPE): This should always be your last line of defence. PPE like respirators, gloves and goggles are essential, but only when other controls cannot bring the exposure down to a safe level.

Following this hierarchy is the backbone of any strong compliance strategy. For more in-depth guidance, feel free to explore our articles on COSHH compliance.

The Importance of Long-Term Record-Keeping

Keeping accurate and organised records is not just good practice; it’s a legal requirement and your proof of compliance. If an HSE inspector walks through your door, they will expect to see detailed records of your risk assessments, air monitoring results and all the control measures you’ve put in place. For some substances, these records must be kept for up to 40 years.

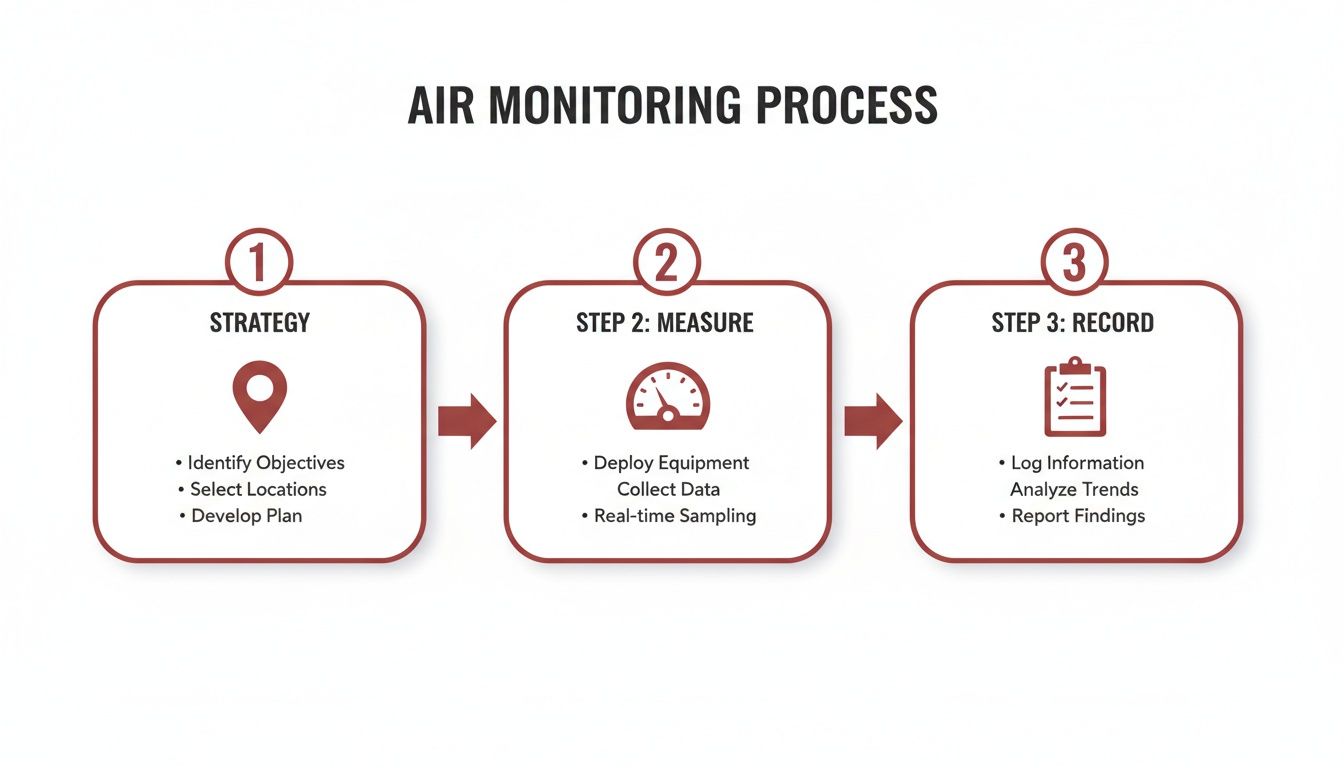

The infographic below shows the simple but critical three-step loop of air monitoring that underpins effective, ongoing compliance.

This cycle of strategy, measurement and recording ensures your safety programme is always built on current, reliable data. The long-term impact is undeniable. Great Britain’s workplace exposure limits have proven their protective power over decades. Just look at the dramatic drop in pneumoconiosis cases after dust limits were introduced—new cases plummeted from a peak of 1,548 in 1972. Consistent adherence to a workplace exposure limit does not just satisfy a regulation; it delivers life-saving results.

Exposure Limits in Specialised UK Industries

While the principles of workplace exposure limits are universal, how they’re applied in the real world varies hugely from one sector to another. The rules for a general factory floor just do not cut it when you’re dealing with the unique hazards in specialised industries. From nuclear power to advanced 3D printing, these environments require their own specific regulations and highly tailored monitoring strategies to keep people safe.

These sectors often involve substances or processes that carry distinct, high-consequence risks you will not find elsewhere. This demands a much deeper understanding of niche legislation and the sophisticated technology needed to manage those challenges, making sure compliance and operational safety go hand-in-hand.

Ionising Radiation in the Energy Sector

The UK’s energy and medical fields work with ionising radiation, a hazard that sits completely outside of standard COSHH guidelines. Instead, exposure is tightly controlled by the Ionising Radiations Regulations 2017 (IRR17). These regulations set strict dose limits for both employees and the general public, which are far more complex than simply measuring a concentration of gas in the air.

These limits are all about minimising the long-term health risks from radiation. Compliance is a two-pronged attack: robust engineering controls like lead shielding, combined with rigorous personal dosimetry where workers wear devices that track their cumulative radiation dose over time.

The UK’s regulations are incredibly effective. Average annual doses for radiation workers are remarkably low; for instance, medical workers get an average of just 0.06 mSv, while the 119,000 registered dental professionals average a tiny 0.005 mSv each year. You can explore more detailed findings on UK radiation exposure levels to see the full impact of these protective measures.

Inert Gas Management in Advanced Manufacturing

Cutting-edge manufacturing processes like 3D printing (additive manufacturing) and industrial heat treatment often depend on inert gases like nitrogen or argon. These gases are used to create a controlled, oxygen-free atmosphere, which is great for the product but poses a hidden danger to people. While not toxic, these gases are a serious asphyxiation risk because they displace the oxygen we need to breathe.

A leak from a sealed chamber or furnace can quickly drop the oxygen level in a room to dangerous levels, leading to disorientation, unconsciousness or worse. The standard WEL framework does not apply here. The real focus is on oxygen depletion monitoring.

In environments using inert gases, the hazard isn’t what’s added to the air, but what’s taken away. The focus shifts from detecting a harmful substance to ensuring a sufficient level of life-sustaining oxygen is always present.

This is where fixed or portable oxygen analysers become absolutely essential. They provide constant monitoring and will sound an alarm if oxygen levels drop below the safe threshold of 19.5%, alerting staff to the invisible danger long before it becomes a crisis.

Emerging Challenges in Hydrogen Production

As the UK pivots towards green energy, the production of blue and green hydrogen is expanding at a massive rate. Hydrogen is highly flammable and carries a significant explosion risk. To make things trickier, it’s also completely colourless and odourless, so a leak is impossible to detect with human senses alone.

Safety in this booming industry hangs on reliable gas detection. A workplace exposure limit for hydrogen is all about its Lower Explosive Limit (LEL), which is 4% by volume in the air. Any monitoring system worth its salt must be able to detect hydrogen concentrations far below this level to give an early warning.

Effective monitoring is therefore paramount for:

- Leak Detection: Finding the source of a hydrogen leak before a dangerous concentration can build up.

- Process Control: Making sure the production, storage and transport systems remain secure.

- Worker Safety: Alerting staff in real-time to potentially explosive atmospheres.

These examples drive home the point that managing workplace exposure limits is never a one-size-fits-all job. From radiation dosimetry to oxygen depletion monitors and hydrogen analysers, having versatile and precise technology is the key to ensuring safety and compliance in the UK’s most demanding industrial environments.

Answering Your Key Questions on Workplace Exposure Limits

Theory is one thing, but what does this all mean on the shop floor? To wrap things up, let’s tackle some of the most common questions managers and employees have about handling workplace exposure limits in the real world.

What Should You Do if a WEL is Exceeded?

First, do not panic, but do act immediately. An exposure limit breach is not something to put off until tomorrow.

Your first job is to find out why it happened. Did a ventilation system fail? Was there a slip-up in safe work procedures, or was it a one-off incident? As soon as you know the cause, you need to implement corrective actions to get things back under control.

Finally, write it all down. You must record the incident, what you did about it and any follow-up monitoring you conduct to prove the problem is solved. This is not just good practice—it’s a vital part of your COSHH compliance paper trail.

How Often Should We Be Conducting Air Monitoring?

There’s no single answer here, as the right frequency depends entirely on your specific risks. Your risk assessment is your guide, but here are the key triggers for monitoring:

- A New Process: When you introduce something new, you need to run initial tests to establish a baseline and see where you stand.

- The Level of Risk: High-risk tasks involving seriously nasty substances will naturally need far more frequent checks than low-risk activities.

- Any Changes: If you tweak a process, switch materials or bring in new equipment, you have to re-monitor. You cannot assume exposures will stay the same.

- Legal Rules: Some substances have legally required monitoring schedules you absolutely must follow.

Think of it this way: regular, scheduled monitoring is your proof that control measures are still doing their job week in, week out.

Can an Employee Refuse to Work Due to Unsafe Exposure?

Yes, absolutely. An employee in the UK has a legal right to refuse to work if they have a genuine and reasonable belief they are in serious and imminent danger. An uncontrolled chemical exposure that blasts past a legal WEL would almost certainly count.

The Employment Rights Act 1996 is clear on this. It protects employees from being penalised if they leave a workplace they reasonably believe poses a serious and imminent threat to their safety. This is a fundamental right for every worker.

If an employee raises this kind of concern, an employer has a duty to investigate it properly and right away. Ignoring it is not an option.

Is There One Universal WEL for All Hazardous Substances?

No, not at all. Every hazardous substance has its own unique toxicological profile—a different way of affecting the human body. Because of this, the Health and Safety Executive (HSE) assigns a specific workplace exposure limit to each one based on hard scientific evidence.

There’s no “one size fits all” number. You must always check the latest official HSE guidance, especially the EH40 Workplace exposure limits document, to find the correct WEL for the specific chemicals, dusts or fumes in your facility.

At Cambridge Sensotec, we know that accurate gas analysis is the bedrock of a safe, compliant workplace. Our range of Rapidox gas analysers delivers the precision and reliability you need to monitor your environment with confidence and keep your team protected. Explore our solutions today to make sure you’re meeting every workplace exposure limit, every time.