Welding Titanium in Inert Gas Atmospheres

There are many reasons an application might call for titanium due to its exceptional strength-to-weight ratio. In its unalloyed form titanium is as strong as some steels yet 45% lighter. However, the welding of titanium demands a more calculated approach that most other metals. Titanium is also very corrosive resistant and nearly as resilient as Platinum. The oxide that grows on the surface is the cause of this resistance and means that Titanium has reduced life-cycle costs, increased service life and is relatively maintenance free. These characteristics make titanium an ideal metal for aerospace, marine, military, chemical, power generation, medical device manufacturing and oil and gas extraction applications.

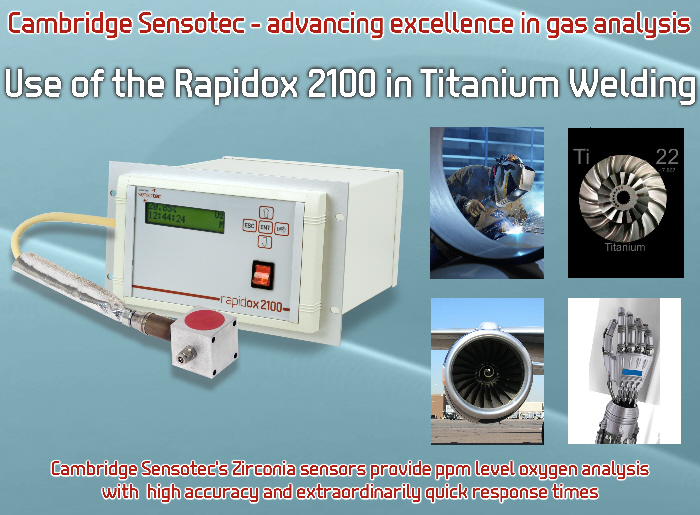

There is little room for error when using shielding gas during titanium welding – 0.005% to be exact. The American Welding Society (AWS) recommends measuring shielding gas purity to ensure weld quality. Most titanium applications call for a 100 percent Argon shielding gas measured to be at least 99.995% pure with no more than 20 parts-per-million (ppm) of oxygen. This is where the Rapidox 2100 oxygen gas analyser can be used to analyse the oxygen levels accurately, providing peace of mind. The zirconia sensor on the Rapidox 2100 will measure oxygen down to 10-20ppm O2, easily covering the range recommended by the AWS. With an extremely fast response time of 4 seconds for a T90 measurement and a high accuracy of +/- 1% of range measured, the Rapidox 2100 can be used to ensure the shielding gas supply is fit for purpose. The Rapidox 2100 is provided with an external zirconia oxygen sensor connected to a 2m cable, which can be extended to 30m; this allows the user to take a measurement from a distance if necessary. The sensor can also withstand pressures of up to 10 bar and can be supplied with an auxiliary pressure sensor. This allows the Rapidox to auto correct for any pressure changes in the shielding gas or to ensure the proper amount is displayed if the user is working with pressurised gas.

Alternatively some titanium welding applications may require dew point measurement. Moisture can have a harmful effect on titanium welding as, similar to aluminium oxide, titanium oxide is hygroscopic so it absorbs moisture from the atmosphere. Welding of titanium components with hydrated layers on the joint surfaces results in increased levels of gaseous hydrogen dissolved in the weld metal and subsequent pore formation upon solidification. The Rapidox 2100 can also be fitted with an auxiliary sensor to measure H2O content from +20oC to -100oC. This allows the user to ensure the level of moisture in the gas will not affect the weld.

The Rapidox 2100 also includes a Type K thermocouple input as standard, for independent temperature measurements up to 1250°C. The auxiliary input can be used to connect an optional pressure, vacuum or dew point sensor that can be simultaneously displayed and data logged. Standard features include fully programmable alarm circuits, programmable analogue outputs (0-5V & 4-20mA), easy calibration (user selectable gases), RS232 / RS485 communications and complete communications / data-logging software which is compatible with MS-Excel. A range of optional pressure, vacuum and dew-point fittings allow the Rapidox to be connected to your apparatus quickly with minimal fuss. This unit has proved so popular that we now sell multi-channel and panel mounted versions, as well as OEM kits.

For further information on gas analysis, please contact us on +44 (0)1480 462142 or email sales@cambridge-sensotec.co.uk. Further details can also be found on our website www.cambridge-sensotec.co.uk